modgas™

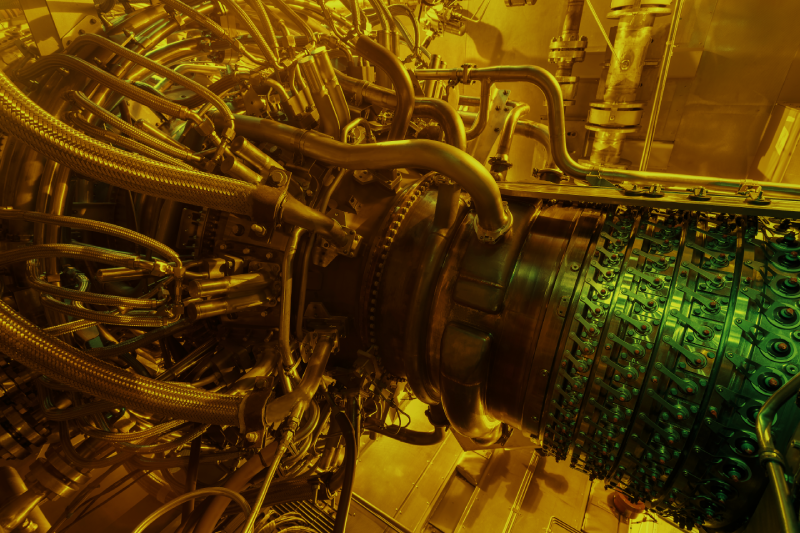

Eta Energy Solutions uses our modgas™ process to help oil and gas firms debottleneck facilities by cost-effectively carrying out major modifications to gas compression systems.

modgas™ is a unique 5-step process that includes:

Requirements Identification - identify current and future operational requirements for the process facility and gas compression system.

Performance Benchmarking - benchmark the operational performance and deliverability of the facility in order to establish an in-service baseline.

Bottleneck Identification - identify opportunities to remove/reduce production bottlenecks and enhance deliverability.

System Redesign - redesign gas compression system in order to overcome bottlenecks.

Redesign Definition - provide a description of the required redesign in an implementable format which provides the basis for major modification work.